Nissens

Nissens ընկերությունն իր տարիների աշխատանքի ընթացքում ներդրել է զգալի միջոցներ շարժիչի հովացման և ավտոմոբիլային կլիմատիկ համակարգերի հետազոտման և ստեղծման համար: Տեխնոլոգիական մշակումների և արտադրության 95-ամյա փորձը թույլ է տալիս բավարարել հաճախորդների պահանջները բարձրորակ ավտոպահեստամասերի լայն տեսականիով, ինչպես նաև սովորեցնել նրանց տվյալ սարքավորումների տեխնիկական ասպեկտները:

Շուկայում որպես տաքացման համակարգի բաղադրիչների առաջատար արտադրող` Nissens ընկերությունն առաջարկում է արտադրանքի կոմպլեքս տեսականի, որն ընդգրկում է ավտոմեքենաների մոդելների մինչև 97 %: Ներառյալ պահեստամասերի բոլոր հնարավոր տարբերակները` ամենավաճառվողից մինչև էկզոտիկ տարբերակներ եվրոպական, ասիական և ամերիկյան մոդելների համար: Nissens-ը հանդիսանում է իդեալական ընտրություն որակի, արտադրանքի տեսականու և մասնագետների որակավորման տեսանկյունից:

Կլիմատիկ սարքավորումներ

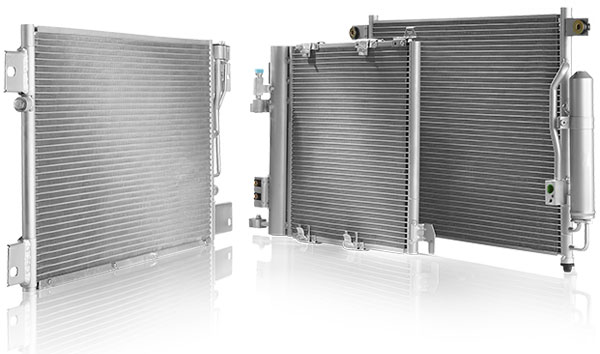

Կոնդենսոր

Սառնագենտի վիճակի փոփոխման համար ծառայող ջերմափոխանակիչ

Կոնդենսորը տեղակայված է ետին բամպերի ետևում և միացված է այլ ջերմափոխանակիչներին` ռադիատորին կամ ինտերկուլերին:

Կոնդենսորի դերը կայանում է նրանում, որպեսզի սառնագենտը գազային վիճակից փոխակերպվի հեղուկի: Վիճակի այսպիսի փոփոխությունը կոչվում է կոնդենսացիա, որի դեպքում սառնագենտի ջերմությունը փոխանցվում է շրջակա միջավայրին:

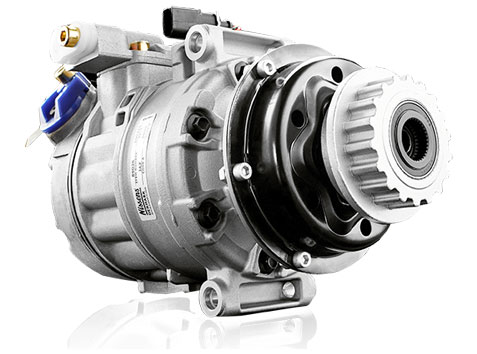

Կոմպրեսոր

Կոմպրեսորը հանդիսանում է օդորակման համակարգի սիրտը

Սառնագենտը սեղմվում է կոմպրեսորի կողմից և շրջանառվում է համակարգում բարձր և ցածր ճնշումների ստեղծման նպատակով:

Կոմպրեսորը հանդիսանում է օդորակման համակարգի արդյունավետության առանցքային մասնիկը: Օդորակման ցիկլի ընթացքում կոմպրեսորը նպաստում է սառնագենտի ձևի փոփոխմանը` գազայինից հեղուկի, սառնագենտի անցմանը համակարգի տարբեր բաղադրիչներով, ինչպես նաև անցմանը բարձր և ցածր ճնշումներով:

Սրահի օդափոխիչ

Ներմղում է օդային հոսքը, ապահովում է շրջանառությունն ու օդի բաշխումը սրահի ներսում, ինչն անհրաժեշտ է օդորակման համակարգի գործառնության համար:

Սրահի օդափոխիչն ապահովում է անհրաժեշտ ծավալի մթնոլորտային օդի ներմղում և նրա անցումը ջերմափոխանակիչներից մեկով`համապատասխանաբար ջեռուցման ռադիատորով կամ գոլորշեցուցիչով: Սրահ է ներթափանցում և տարածվում ավտոմեքենայից դուրս օդի ջերմաստիճանի համեմատ ավելի տաք կամ սառը օդ: Որպես կանոն սրահի օդափոխիչը տեղակայված է ջեռուցման, օդափոխման և օդորակման մոդուլում, որը գտնվում է ավտոմեքենայի սրահի և շարժիչի խցիկի արանքում:

Սրահի օդափոխման համակարգը հանդիսանում է բավականին փխրուն էլեկտրական սարքավորում, առկա պլաստամսե էլեմենտների պատճառով, ինչպես նաև այն զգայում է ավտոմեքենայի էլեկտրական համակարգերի խափանման հանդեպ:

Զտիչ-չորացուցիչ/Մարտկոց-չորացուցիչ

Իրականացնում է կոնտուրի պաշտպանման գործառույթ

Զտիչ-չորացուցիչը զտող տարր է, որը տեղադրված է կոնտուրի բարձր ճնշման հատվածում` կոնդենսորի և ընդլայնող փականի մեջտեղում: Զտիչ-չորացուցիչի դերը խառնուրդների, մասնիկների և խոնավության կլանումն է:Բացի այդ սա սառնագենտի և յուղի պահպանման վայր է:

Մարտկոց-չորացուցիչը նմանատիպ սարք է, սակայն կիրառվում է այն ավտոմեքենաներում, որոնցում ընդլայնող սարքը հանդիսանում է ընդլայնող խողովակը: Տեղակայված է ցածր ճնշման տարածքում և բացի նմանատիպ գործառույթներից` զտում և յուղի/սառնագետնի պահոց, ունի լրացուցիչ խնդիր` պաշտպանում է կոմպրեսորը հեղուկ վիճակում սառնագենտի ներթափանցումից:

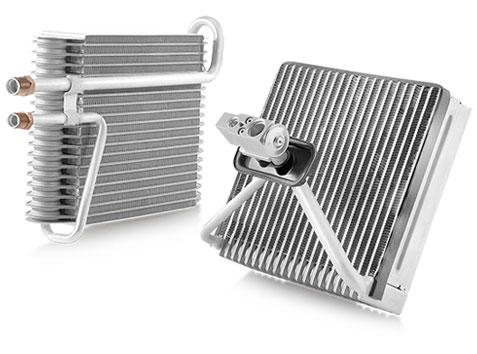

Գոլորշեցուցիչ

Օդի սառեցման համար նախատեսված ջերմափոխանակիչ

Օդորակման համակարգի ցածր ճնշման հատվածում ընդլայնող փականի և կոմպրեսորի մեջտեղում է տեղակայված ջերմափոխանակիչը:Սովորաբար տեղադրված է ջեռուցման, օդափոխման և օդորակման մոդուլում, որը գտնվում է ավտոմեքենայի սրահի շարժիչի հատվածի միջնամասում:

Գոլորշեցուցիչի մակերեսին ներմղվող մթնոլորտային օդը նպաստում է գոլորշեցուցիչի ներսում սառնագենտի գոլորշիացմանը, հեղուկ վիճակից անցմանը գազի: Գոլորշեցուցիչի մակերեսից անցնող օդը սառում է և տեղափոխվում ավտոմեքենայի սրահ:

Գոլորշեցուցիչը կատարում է ևս մեկ ոչ պակաս կարևոր գործառույթ` սրահ մտնող օդի չորացում, ինչը շատ կարևոր է ավտոմեքենայում ապակիների խոնավեցումը կանխելու համար:

Ջեռուցիչի ռադիատոր

Տաք օդի արտադրություն և ապակիների խոնավեցման վերացում

Ջեռուցիչի ռադիատորը շարժիչի հովացման համակարգի անբաժան մասն է: Չնայած դրան` այս ջերմափախանակիչը զգալի աջակցություն է ցուցաբերում օդորակման համակարգին` արտադրելով տաք օդ:

Այն սովորաբար տեղակայված է ջեռուցման մոդուլի գործիքների վահանակի, օդափոխման և օդորակման համակարգերի ներսում:

Տաք սառեցնող հեղուկն անցնում է ջեռուցիչի ռադիատորով և տաքացնում է սրահի օդափոխիչի կողմից դեպի սրահ մղվող օդը: Ջեռուցիչի ռադիատորից դեպի ավտոմեքենայի ապակիներն ուղղված տաք օդը հեռացնում է նրանց խոնավեցումը, ինչը շատ կարևոր է ցուրտ եղանակին անվտանգ երթևեկելու համար:

Օդորակման համակարգի օդափոխիչ

Համակարգի կարևոր բաղադիչ

Օդափոխիչն ունի կարևոր օժանդակ դեր շարժիչի հովացման համակարգի արդյունավետ աշխատանքի և օդորակման հարցում: Օդորակման համակարգում օդափոխիչը ներմղում է օդի հոսքը դեպի կոնդենսոր:

Կոնդենսացման ամբողջական գործընթացն ապահովելու համար պահանջվում է կոնդենսորի օդի լրացուցիչ օդափոխություն, որի մակերեսին տեղի է ունենում շրջակա օդի և սառնագենտի միջև ջերմափոխանցում: Օդափոխիչի կողմից ստեղծված օդային հոսքը շատ կարևոր է կոնդենսորի աշխատանքի համար:

Շարժիչի հովացում

Ռադիատոր

Շարժիչի ջերմակարգավորման համար անհրաժեշտ ջերմափոխանակիչ

Ռադիատորը գտնվում է ավտոմեքենայի սկզբնամասում մյուս ջերմափոխանակիչների հետ միասին` ինտերկուլեր և կոնդենսոր:

Ռադիատորի դերը ներքին այրման շարժիչի հովացումն է: Շարժիչներում մեկ րոպեում կարող է տեղի ունենալ այրվող խառնուրդի մինչև 6000 բռնկում: Յուրաքանչյուր բռնկումից հետո արտադրվում է 1500 °C տաքություն: Խոնավեցնող հեղուկը շրջանառում է մխոցի բլոկի հովացման շապիկով` վերցնելով մխոցի բլոկի և շարժիչի դետալների ջերմությունը:

Հովացման հեղուկը, շարժիչում ստանալով վառելիքի այրման հետևանքով առաջացած ջերմությունը, կրկին սառչում է, հոսելով ռադիատորով, որը փոխանցում է տաքությունը մթնոլորտային օդին:

Յուղի ռադիատորներ

Շարժիչի յուղի հովացում և տրանսմիսիա

Դետալներն օծելու համար նախատեսված յուղն ունի իր ներդրումը հովացման հարցում: Յուղային ռադիատորն ընդունում է օծող յուղի տաքությունը և փոխանցում շրջակա օդին:

Սովորաբար յուղային ռադիատորը կիրառվում է փոխանցման տուփի կամ հիդրավլիկ սարքի յուղի հովացման համար:

Առանձին ջերմափոխանակիչով շարժիչի յուղի հովացմամբ ավտոմեքենաներն արդեն սովորական երևույթ են: Ավելի հաճախ յուղի հովացուցիչները կիրառվում են փոքր չափերով ավտոմեքենաների համար և այն տեխնիկայի համար, որն աշխատում է բարդ պայմաններում:

Ժամանակակից ավտոմեքենաներում փոխանցման տուփի յուղահովացուցիչը հաճախ հանդիսանում է ավտոնոմ էլեմենտ և շարժիչի բաժնում տեղադրվում է այն բաղադրիչներից առանձին կամ շարժիչի բլոկում:

Օդափոխիչի կցորդիչ

Կցորդիչը փոխում է օդափոխիչի պտույտների հաճախականությունը

Կցորդիչը հանդիսանում է օդափոխիչի պտույտների հաճախականությունը կառավարող սարք: Կցորդիչի ներսում առկա փականը կարգավորում է հատուկ սիլիկոնե յուղի հոսքը, ինչի հետևանքով գործարկվում է օդափոխիչը:

Կցորդիչը նպաստում է շարժիչի հզորության տնտեսմանը, որը ծախսվում է օդափոխիչի պտույտների համար: Կցորդիչները բաժանվում են երկու տիպի` բիմետալիկ տվիչով և ազդանշանների միջոցով էլեկտրոնային կառավարմամբ:

Ազդանշանների բնույթի վրա ազդում են շարժիչում յուղի ջերմաստիճանը/տրանսմիսիաները, հովացման հեղուկի ջերմաստիճանը, հովացման կոնտուրում ճնշումը և շրջակա օդի ջերմաստիճանը: